TOLON Equipment

Full service equipment sales, installation, and service

With a TOLON Distributorship, we have a choice for every customer.

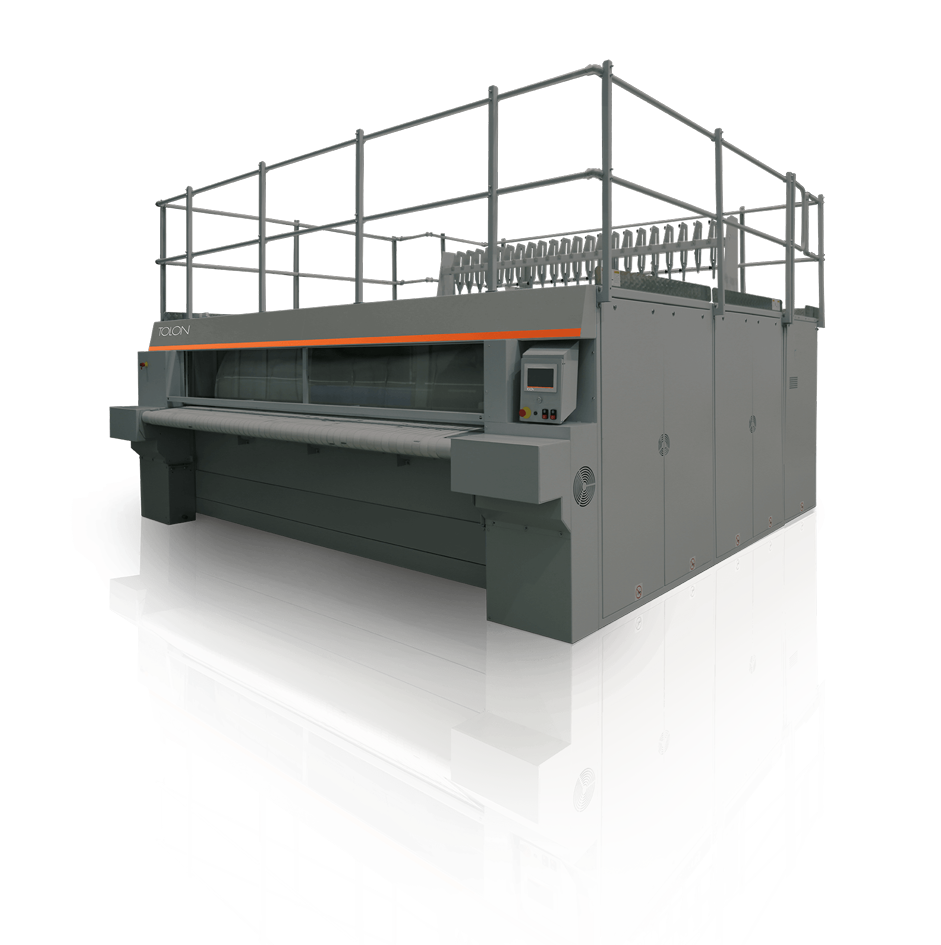

Ironers

STANDARD FEATURES & BENEFITS

• Ergonomic cylinder heated ironer

• Electric or gas heating

• Chromated roll for better thermal conduction and highly resistant to corrosion, even after periods of inactivity

• Large surface contact with linen

• Front return of the linen

• Extended heat transfer path

• Easy to use electronic control with pre-set ironing programmes

• Indication of ironing temperature and speed

• Overheating check system with 1 or 2 temperature sensors

• Premix burner for more power and efficient ironing

• Frequency controlled motor

OPTIONS (for TFI 6026-6032)

• Longitudinal Fold

• Rear exit for the linen

• 3 folding sensors at feeding point instead of 1

• Transport wheels

STANDARD FEATURES & BENEFITS

Flexible chest – The flexibility allows it to adapt to the actual roll diameter, maintaining a long-life high quality performance through, optimal and stable contact angle and higher evaporation capacity.

Compared with stainless steel, carbon steel offers lower friction with wet linen and has higher thermal conduction, maintaining higher and more even temperatures for higher quality iron.

Planetary gear minimizes the counter torque and ensures that the roll will stay in its centered position during operation.

Exhaust control to reduce moisture in padding and prevent the roll from cooling down

Adjustable speed with adjustable V-belt pulleys

A steam-free ironing solution, the heat comes from a gas-fired burner

Relatively low weight of flexible chest allows faster and more energy efficiency heat up

An oil expansion tank connected to the heat exchanger

Oil heating medium up to 40% higher heat transfer efficiency

Optimum Production and Finishing Quality

Chest temperature up to 446° F (104° F higher than that of steam with 12 bar of pressure).

Precise Temperature control using an intelligent burner, modulating between different flame sizes depending on the required speed and evaporation capacity.

Minimal installation and set up, simply to be set in place and hooked up to a gas supply.

Easy to operation and control

Both the main and the analog control panels can monitor the performance of the ironer

Low maintenance technologies, the only regular maintenance is keeping cleaning and changing the oil of the gear boxes.

OPTIONS

3 different types of feeding tables

Standard width feeding table, 15.7″ mm with separate toothed belt drive and with variable speed.

Optional extended inclined inlet table, width 23.6″ mm with shortened feeding height is ideal for smaller and larger linen offering ergonomic working conditions and excellent visual inspection of linen. It is especially suited for round table linen as it allows for careful guiding into ironer.

Optional incorporated vacuum box to ensure optimum feeding quality of large as well as small pieces.